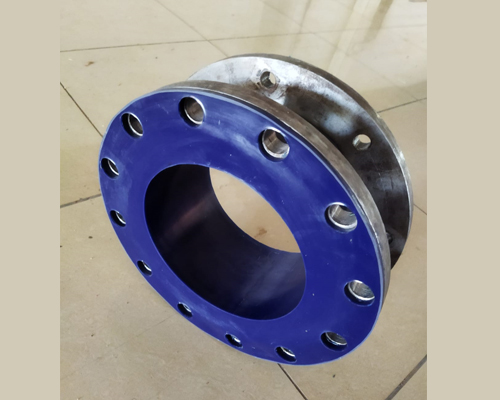

Jawstech offers various hydrocyclone parts with different grades of Polyurethane Material. It has the characteristics of high wear resistance, high strength, lightweight, and long service life

We offer high strength low weight PU elastomer Structure. We developed our PU Hydro cyclone parts which outperform other brands with its high impingement abrasion. Cyclone Parts We offer:

Hydro cyclones are integral components in the realm of fluid dynamics and separation processes, playing a pivotal role in industries such as mining, mineral processing, water treatment, and oil and gas. Understanding the intricate components of a hydro cyclone provides insights into its functioning and underscores its significance in efficiently separating particles from liquids based on their size and density.

Feed Inlet: The hydro cyclone process begins with the introduction of a mixture of liquid and particles through the feed inlet. This initial section sets the stage for the subsequent separation process.

Cone Angle: The conical body is a key feature of a hydro cyclone. The cone angle determines the residence time of particles within the cyclone and influences the separation efficiency. A steeper cone angle generally results in a shorter residence time.

Vortex Finder Diameter: Located at the top of the hydro cyclone, the vortex finder is a cylindrical structure that establishes the core vortex. The diameter of the vortex finder influences the cut size of the cyclone, determining the size of particles that will be carried in the overflow.

Apex Diameter: Positioned at the bottom of the hydro cyclone, the apex serves as the outlet for the underflow stream. The apex diameter plays a crucial role in controlling the volume and velocity of the underflow discharge.

Overflow Outlet: The overflow outlet, situated at the top of the cyclone, allows the separated liquid to exit. This stream typically contains finer particles that are carried away with the liquid.

Underflow Outlet: The underflow outlet, located at the bottom, facilitates the discharge of the heavier particles that have been separated from the liquid. The underflow is characterized by its higher density.

Formation of Air Core: As the mixture spirals downward within the hydro cyclone, an air core is formed at the center. This air core is crucial in maintaining the stability and efficiency of the separation process.

Wear-Resistant Liner: The internal surfaces of hydro cyclones are often lined with wear-resistant materials to withstand the abrasive nature of particles within the slurry. Common liner materials include rubber or ceramic.

Corrosion-Resistant Materials: Hydro cyclones are constructed using materials that resist corrosion, ensuring longevity and reliability, especially in industries dealing with aggressive or corrosive fluids.

Hydro cyclones are widely used in mining operations to separate valuable minerals from ore slurries based on particle size and density.

In water treatment plants, hydro cyclones assist in removing impurities, sediments, and particles from water, contributing to the production of clean and clarified water.

Hydro cyclones play a role in separating oil and water in oil and gas processing, aiding in the extraction and refinement of hydrocarbons.

Hydro cyclones efficiently separate particles of different sizes and densities, offering high separation efficiency.

The compact nature of hydro cyclones makes them suitable for applications where space is a critical factor.

With fewer moving parts, hydro cyclones are known for their low maintenance requirements, contributing to cost-effectiveness.

Hydro cyclones can be adapted to various applications by adjusting design parameters such as cone angle and vortex finder diameter.

The nuanced components of hydro cyclones collectively orchestrate a symphony of separation, making them indispensable in industries where precise particle classification is paramount. The continuous evolution of hydro cyclone technology ensures their relevance in diverse applications, contributing to enhanced efficiency and sustainability across various industrial landscapes.

Also, we have the ability to manufacture any customized PU Hydro cyclone parts with customer requirements.

Pipeline wear failure is always a challenge to process industries, especially for the industries carrying slurry, aggregates, oil, and Gas. our pipeline PU Coating has a reversible deformation process, reducing impingement abrasion to its minimum.