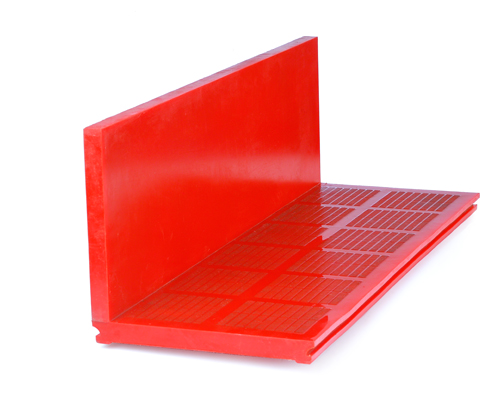

Jaws Tech has a unique benchmark for its polyurethane screening and dewatering media. We achieved it through our continuous quality improvement process and real-time site feedback.

Elastomer grades used in JAWS TECH screens are mining-grade virgin PU polymers that perform effectively in wet and dry applications.

Screening and dewatering solutions are vital processes in various industries, playing a key role in the efficient separation and management of materials. These solutions are employed across sectors such as mining, aggregates, wastewater treatment, and industrial processing, where the effective separation of solids and liquids is crucial for optimizing operations and meeting quality standards.

Screening is a fundamental process in industries that deal with bulk materials, allowing for the separation of particles based on size, shape, or other characteristics. The primary objective of screening solutions is to categorize materials into different fractions, ensuring that only particles of the desired size or quality pass through. This process is essential for a variety of applications, from mining and construction to agriculture and recycling.

Vibrating screens use vibratory motion to separate materials based on size. They are widely used in applications ranging from mineral processing to aggregate screening.

Trommel screens are cylindrical screens with perforated surfaces that rotate, effectively sorting materials by size. They are commonly used in mining and municipal solid waste processing.

These screens utilize a rotating drum to separate materials. Rotary screens are versatile and find applications in wastewater treatment, food processing, and more.

Flat deck screens provide a flat surface for material separation and are often used in applications where a gentle screening process is required.

Dewatering is the process of removing excess water from solids, typically after the screening or washing process. Dewatering solutions are critical in industries where the moisture content of the final product needs to be controlled, such as in mineral processing, sludge management, and aggregate production.

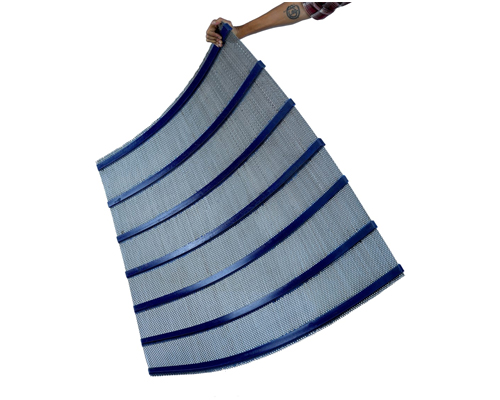

These screens are designed to remove water from material, providing a dry and stackable output. They find applications in sand dewatering, coal processing, and more.

Centrifuges use centrifugal force to separate liquids from solids. They are employed in various industries, including wastewater treatment, food processing, and pharmaceuticals.

Filter presses apply pressure to separate water from sludge or slurry, producing a filter cake with reduced moisture content. They are commonly used in industrial processes and municipal wastewater treatment.

Screw presses use a screw mechanism to compress and dewater materials. They are efficient in applications like pulp and paper, food processing, and wastewater treatment.

Screening and dewatering solutions are crucial in mining and aggregates industries for separating valuable minerals or aggregates from unwanted materials and managing water content for efficient processing.

In wastewater treatment plants, these solutions help in removing solids and excess water from sewage or industrial effluents, contributing to the production of treated water and dewatered sludge.

Screening and dewatering play a role in the recycling of construction and demolition waste by separating recyclable materials and managing moisture content.

Industries such as food processing utilize these solutions for separating solids from liquids and controlling moisture content in various food products.

These solutions enhance overall process efficiency by separating materials effectively and managing moisture content.

In mining and recycling, screening solutions contribute to the recovery of valuable resources from raw materials.

Dewatering solutions assist in meeting environmental standards by reducing the volume of wastewater or sludge requiring disposal.

Controlling moisture content improves the quality of final products, ensuring they meet desired specifications.

Screening and dewatering solutions are integral to numerous industries, contributing to efficient material separation, moisture control, and resource recovery. The continuous development of innovative technologies in this field ensures that these solutions remain essential for industries striving for operational excellence, environmental compliance, and the production of high-quality products.